MACHINE & SAFETY AUTOMATION

Risk assessment studies and reporting are conducted based on the Machinery Safety Regulation (2006/42/EC) and the latest published standards in the EU standards for Industrial Machinery and Production Lines.

Analyses of accidents are conducted based on the following elements:

- Human-induced hazards

- Design-related hazards

- Electrical hazards

- Physical and chemical hazards

- Example accident investigations

Some of the regulations and standards taken into account during the risk assessment are as follows:

- Machinery Safety Regulation – 2006/42/AT

- Safety of machinery – General principles for design – Risk assessment and risk reduction (ISO 12100:2010)

- EN/IEC 61508: Functional safety of electrical/electronic/programmable electronic safety-related systems in terms of safety-related aspects

- EN/IEC 61511: Functional safety – Safety instrumented systems for the process industry sector

- EN/IEC 62061: Safety of machinery – Functional safety of electrical, electronic, and programmable electronic control systems for safety-related parts

- EN 954: Safety of machinery – Safety-related parts of control systems

- EN ISO 13849: Safety of machinery – Safety-related parts of control systems

- EN ISO 13857:2008 Safety distances for preventing hazard zones being reached by upper and lower limbs

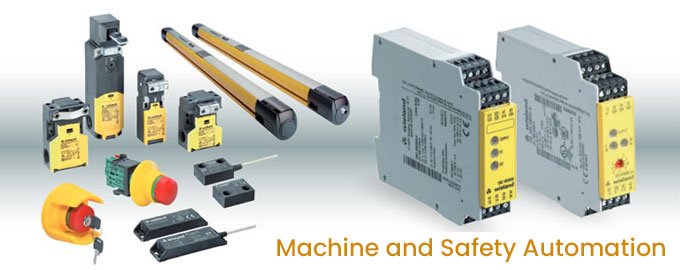

After the risk assessment, the safety design of the system is performed, determining the category and Safety Performance Level (PL) for each risk. Based on this data, field safety equipment (Emergency stop, Light curtain, Door monitoring, Safety PLC, etc.) is identified and implemented.

After the implementation, each safety function related to a risk is tested for verification and reported.

Our Solutions

- Automation Solutions

- Data Collection and IoT Solutions

- Augmented Reality (AR)

- MES-MOM Solutions

- Machine and Safety Automation

- Eccentric and Hydraulic Press Automation

- Transformer Fan Control Panels

- Transformer Tap Changer RTCC (AVR) Panel

- L.V Distribution and Lighting Panels

- Compensation Panels

- Motor Control (MCC) Panels

- Electric Meter Panels

- Electrical Project and Design

- Panel Manufacturing and Assembly