DATA COLLECTION & IoT SOLUTIONS

The importance of data in industrial environments is significant. In many cases, this data is manually collected and entered into the system by someone.

The three common issues related to data collected manually are excellence, inaccuracy, and delay. Considering that raw data collected from production forms the basis of all subsequent production reports and that significant decisions rely on these reports, any problem in the initial data collection can trigger ripple effects that may adversely affect your business.

The data collected from the field enables production planning, efficiency analysis, cost and downtime analysis, and the planning of stabilization and maintenance activities. Data collection from production is a crucial and error-free requirement for the factory. Therefore, automating and ensuring the accuracy of the data collection process from production brings significant benefits to businesses.

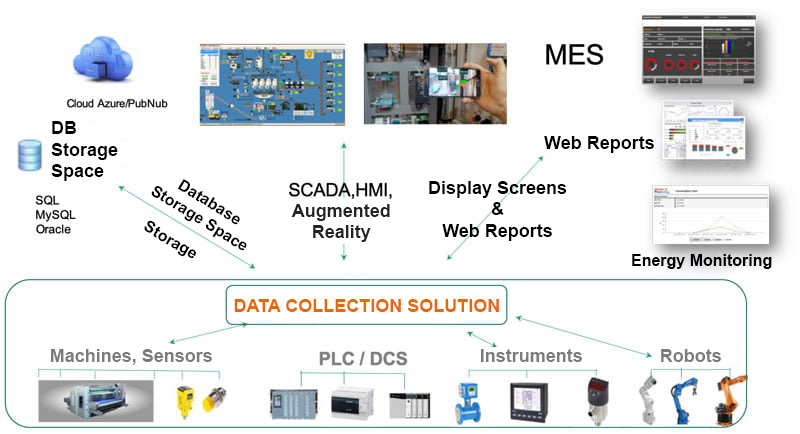

Epm Otomasyon, our advanced production data collection systems (OPC Server, Modbus Protocols Converters, IoT Gateway, Panel Solutions) enable communication with automation systems consisting of PLC/DCS, sensors, robots, and other devices. We collect real-time data and provide integration services to databases (SQL, ERP, MES, etc.). The first stage of Industrial IoT (IIoT) is the connection of data sources within the facility to each other and to the Cloud, according to the project.

- Controlling machines with PLC using Ethernet communication, if Ethernet/IP is available, we convert it to Ethernet/IP, and if Modbus RS485 is available, we convert it to Ethernet/IP using converters. This way, we send the desired production data to a database like SQL and later analyze it on a platform such as MES

- If the system is very old, lacks communication ports on the PLC, or there is no PLC, we can connect the signals to Remote I/Os with Ethernet/IP or EtherCAT communication ports and send the data upstream (to MES, ERP, etc.)

- If there are no sensors, we can obtain production quantity and other data by adding additional sensors

- For energy consumption, we can connect an energy analyzer to each machine or even to analyze and report electricity consumption. We can also obtain water and gas consumption from flow meters and natural gas meters, sending the data to the control system for analysis and reporting.

- We enable you to have state-of-the-art technologies such as LoRaWan and NB-IoT with plug-and-play Smart IoT Devices, making it possible to send data from devices to the Cloud or from the Cloud to devices using bidirectional communication protocols specially designed for IoT, such as MQTT.

- Depending on the structure of your factory, we provide both wireless (WI-FI) and wired communication options.

The ability to monitor and analyze all machinery and equipment in your factory in real-time

- Accuracy and speed of data collection from production improves

- Enables you to identify the real causes of productivity loss

- Contributes to the effectiveness of advanced planning systems by providing accurate and real-time data

- Provides the opportunity for long-term analysis to better understand the impact of changes or new strategies

- Critical process data is collected for your quality standards

- Supports green and sustainable manufacturing through efficient use of resources and a paperless environment

Ensures you achieve the benefits mentioned above and many more.

For more information, please send an email to info@epmotomasyon.com.tr. When you contact us, our experts and experienced team will come to your place and perform the necessary research and analysis. Based on the conducted research and analysis, projects are prepared as per your requirements and presented to you, our customers.

Our Solutions

- Automation Solutions

- Data Collection and IoT Solutions

- Augmented Reality (AR)

- MES-MOM Solutions

- Machine and Safety Automation

- Eccentric and Hydraulic Press Automation

- Transformer Fan Control Panels

- Transformer Tap Changer RTCC (AVR) Panel

- L.V Distribution and Lighting Panels

- Compensation Panels

- Motor Control (MCC) Panels

- Electric Meter Panels

- Electrical Project and Design

- Panel Manufacturing and Assembly